Water Closet for October 3, 2014

Water in its unseen state has been rarely mentioned in the Water Closet’s nine years. The other day talented Middleton artisan1 Carl Close called an old Stream Teamer and invited him to watch his steam boiler and engine, no toys, in action. The Stream Teamer picked up another and off they went to see Carl’s work of art, much admired previously even when not running.[pullquote]”We urge you to Google steam engines on the computer for explanations including some nice animated displays”[/pullquote]

On the back lawn near a full sized sawmill, also made by their host, stood a black boiler about shoulder high and one foot in diameter. After greeting us, Carl started a fire in the firebox and fed it small scraps of wood. We were seated in molded plastic chairs contrasting sharply with the homemade boiler and handsome red engine nearby connected by a steel reinforced hose. The whole was crafted by Carl who upturned a short log and sat with us, his audience. We all checked the pressure gauge; its needle after ten minutes of fire below the boiler was still on zero. Questions were asked and answered by the designer and maker of these old fashioned devices so important in the 18th and 19th centuries. They were the power underlying the Industrial Revolution. Steam from coal, now through turbines provides most of our electricity. Carl summed the basic process up briefly with something like, “Take water, boil it, make steam, and you get useful power.” It had taken almost 1700 years since Hero of Alexandria made a steam powered toy until the “useful” was achieved. Then in the 18th century stream power technology exploded, sometimes literally, and the Industrial Revolution was underway. Clever folks like our host designed scores of steam engines for various uses. By the end of the 19th century there were millions worldwide transporting people and goods, and doing much of societies’ heavy lifting. Coupled with this growth was the massive use of fossil fuels and recent wood from photosynthesis to heat the water. All along our large rivers great piles of coal or wood were at stations for stream boats.  Air pollution resulted. Carl’s boiler produces little smoke, less than that from a small charcoal grill or from his forge. He is also a blacksmith.

Air pollution resulted. Carl’s boiler produces little smoke, less than that from a small charcoal grill or from his forge. He is also a blacksmith.

In the 20th century internal combustion engines took over and largely phased out steam except for the production of electricity in steam-turbine powered plants.

The old timers observing Carl and his creations remembered train locomotives exhausting steam upon braking while entering stations. It condensed into clouds of liquid water droplets with much noise and drama. Tolstoy in his famous novel has condensing steam swirling around Anna Karenina as she leaps in front of a locomotive and leaves her guilt behind. Finally the boiler gauge showed signs of pressure; engineer Carl rose to tend his valves. A couple valves emanating steam and hot water needed tightening. Wrenches were brought forth and with the observers eager help the leaks were sealed. Twenty minutes or so after the boiler was fired the pressure crept up to 15 pounds-per-square-inch and the engineer opened the valve which let steam to his engine. He cranked the two foot diameter flywheel and soon the engine was quietly, to one guest’s surprise, running smoothly without vibration. Carl and friends settled down to watch as questions continued and were answered by the engineer who frequently rose to add wood to the fire and adjust the throttle valve. He as in the old railroad movies had an oil can handy. The lubrication by a dilute oil and water mix, heavy oil, and babbitt bearings is interesting and an important part of steam engines. We owners of modern vehicles had almost forgotten crawling under cars of old with grease guns. Carl’s guests kidded him for not having a vehicle powered by the engine. He could then drive around town giving folks a look at the Stanley Steamer car days at the end of the 19th century. We Stream Teamers would of course ride with him at every opportunity. He had in the past attached a belt to the flywheel to power a cordwood saw. A vehicle would be a cinch for Carl. He already has a pickup truck so sadly such a vehicle isn’t needed.

After sitting with this relatively new but old fashioned beauty for a while on a fine fall day, we visiting old timers were reluctant to leave this red painted and polished bronze machine made from scratch in almost every detail by a friend. Parts were forged or turned out on a lathe and milling machine. The frame parts supporting flywheel, piston, condenser, rods, and belts were welded together and finished off so well it appears cast to knowledgeable observers at engine shows. You’d think the whole had been put together in a factory by craftsmen specializing in this type of engine.

Rarely discussed water vapor was the subject we started with here. A liter of water completely vaporized at atmospheric pressure would need a 1700 liter container to hold the gas, so in going from liquid water to vapor produces enormous pressure.2 It is this pressure that does the work within strong enclosures with moving pistons. We urge you to Google steam engines on the computer for explanations including some nice animated displays. Expansions and contractions move pistons hooked up to shafts, arms and wheels up and down and round and round, voila an engine! On a larger atmospheric scale evaporation and condensation are what accounts for much of our weather and even our feelings on muggy to dry days.

Oservant tinkerers over the centuries “using trial and error,” a favorite phrase of Carl’s, obtained power from liquid going to gas and back. There is something very fine about work from water. Maybe new generations of inventors, scientists, and engineers using trial and error will come up with something besides fossil fuels and iffy nuclear power to heat water.3 They have. Some say focused solar energy is the answer. Right now the solutions are largely a matter of efficiency, economics, and will.

1 Artisan. 1. An artist. 2. One trained in some mechanic art or trade. Webster New Collegiate Dictionary, 1951. We know Carl learned by observing and then trying, or trying and observing, which is what wise “trial and error” is.

2 Most of the early 20th century locomotives operated at boiler pressures between 175 and 250 pounds per square inch.

3 It takes a lot of energy to move the snuggling-slip-sliding-around water molecules of liquid to a speed where they part and bounce around as vapor. It takes 540 calories to vaporize 1 gram of liquid water.

_________________________________________________________________________

WATER RESOURCE AND CONSERVATION INFORMATION

FOR MIDDLETON, BOXFORD AND TOPSFIELD

| Precipitation Data* for Month of: | June | July | Aug | Sept | |

| 30 Year Normal (1981 – 2010) Inches | 3.95 | 3.89 | 3.37 | 3.77 | |

| 2013 – 14 Central Watershed Actual | 2.03 | 7.26 | 2.20 | 1.6 as of 9/30* | |

Ipswich R. Flow Rate(S. Middleton USGS Gage) in Cubic Feet/ Second (CFS):

For Sept 30, 2014 Normal . . . 8.1 CFS Current Rate . . . Unavailable

*Danvers Water Filtration Plant, Lake Street, Middleton is the source for actual precipitation data thru Sept. Normalsdata is from the National Climatic Data Center.

THE WATER CLOSET is provided by the Middleton Stream Team: www.middletonstreamteam.org or <MSTMiddletonMA@gmail.com> or (978) 777-4584

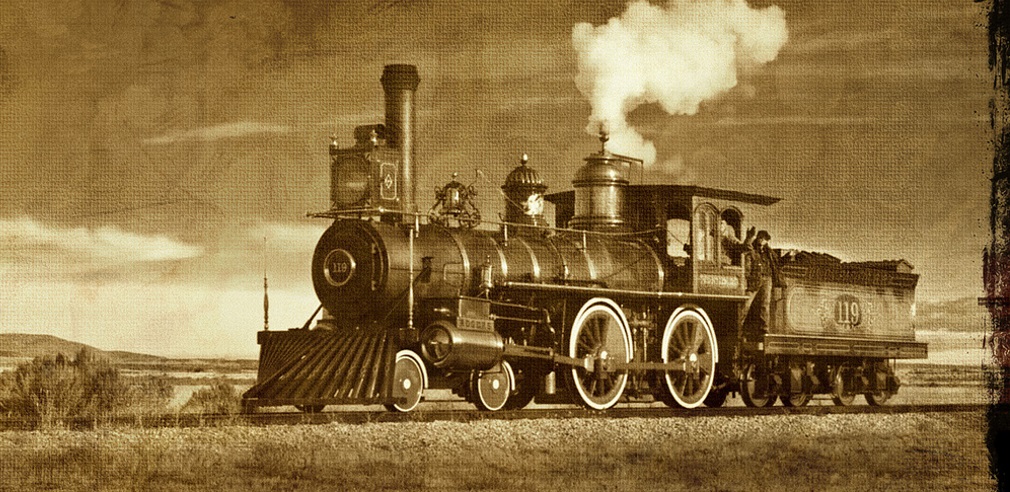

Featured Photo credit: Just Used Pixels via photopin cc